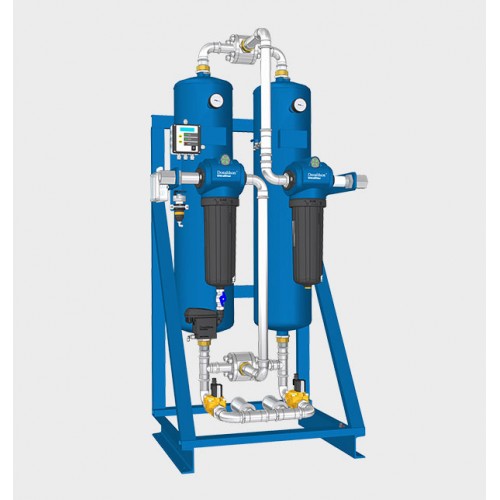

Ultrapac HL High Pressure Heatless Adsorption Dryer

The HL series of high pressure heatless adsorption dryer from Donaldson (Germany) is designed for drying of compressed air and nitrogen in a pressure range up to 16 bar.

Ultrapac™ HL-ALD / HL-MSD heatless desiccant compressed air dryers benefit from decades of design and fabrication experience by Donaldson.

Ultrapac HL-ALD / HL-MSD heatless desiccant compressed air dryers benefit from decades of design and fabrication experience by Donaldson.

Our dryers are designed to consistently provide highly purified quality air with high energy efficiency in a flow range from 100 to 8,750 m3/h at 7 bar g.

Operation is fully automatic with a guaranteed outlet dew point at one of two pre-selected settings: ALD, -40° C ; MSD, -40°C to -70 °C depending on operating conditions and sizing.

All Ultrapac HL dryers are supplied with preinstalled pre-filters and after-filters using UltraPleatTM technology. The coalescing pre-filter is equipped with the Ultramat™ zero-loss condensate drain.

The compact design of Ultrapac HL dryers takes up a minimum of floor space.

Maximum efficiency and the highest operational safety, coupled with low operational costs are attributes that convey the advantages of the adsorption dryer. The areas of application are diverse and are matched to the exact requirements of the customer.

The time-controlled adsorption dryer without capacity control operates with a predetermined cycle time for which the dryers are designed, irrespective whether the desiccant might be utilized to the maximum. The dryer’s requirement for regeneration air (energy consumption of compressed air) therewith remains constant.

Industries:

- Industrial Machinery

- Food Processing

- Electronics

- Automotive

Features & benefits:

The Ultrapac HL - range is designed for drying of compressed air and nitrogen in a pressure range up to 16 bar.

The drying process is based on adsorption of water molecules out of a gas stream on hygroscopic desiccant materials. With this drying concept pressure dewpoints of -40В°C (at 7 bar) or lower can be achieved.

The regeneration of saturated desiccant is done by using a partial steam of dry compressed air for the desorption of water.

Pre filter with automatic electronical condensate drain and after filter are included in the Ultrapac purification system.

An electrical circuit board controller enables automated con-trol of all phases of the drying and regeneration cycle.

It includes the dewpoint monitoring and control system Ultraconomy for energy efficient and reliable operation in the Superplus models.

|

HL-ALD HL-MSD |

Nominal Volume Flow (1 bar, 20°C) m3/h1) |

Pure Air Consumption, |

Volume Flow Outlet, Min. m3/h (1 bar, 20°C) |

Differential Pressure, initial mbar |

Pre- and after-filter UltraPleat S |

||

|

ALD |

MSD |

ALD |

MSD |

||||

|

0100 |

100 |

15,0 |

20 |

81.6 |

75.4 |

7.8 |

0210 |

|

0150 |

150 |

23.0 |

30 |

121.7 |

113.1 |

11.2 |

0210 |

|

0175 |

175 |

26.3 |

35 |

142.7 |

132,0 |

11.2 |

0210 |

|

0225 |

225 |

34,0 |

45 |

183.2 |

170,0 |

14.2 |

0450 |

|

0300 |

300 |

45,0 |

60 |

244.7 |

226.2 |

14.2 |

0450 |

|

0375 |

375 |

56,0 |

75 |

306.1 |

282,8 |

20,0 |

0450 |

|

0550 |

550 |

83,0 |

110 |

447,9 |

414.7 |

24,0 |

0600 |

|

0650 |

650 |

98,0 |

130 |

529.5 |

490.1 |

32.5 |

0750 |

|

0850 |

850 |

128,0 |

170 |

692,6 |

640,9 |

32.5 |

1100 |

|

1000 |

1000 |

150,0 |

200 |

815,5 |

754,0 |

38,0 |

1100 |

1) Nominal flow at 7 bar g, 35°C